Industrial

IFM has spent over a decade developing expertise in industrial tooling fabrication and MIL spec welding. With our new facility, plus the addition of in-house waterjet processing and destructive weld testing, we are more capable than ever to assist integrators and OEMs with weldment fabrication and assembly.

With an on-staff AWS Certified Welding Inspector/Educator, IFM is able to offer certified welding and fabrication services in compliance with most technical requirements, with minimal outside support.

Please see our Certified Welding page for details on welding capabilities and compliance

Capabilities

- Weldments up to 5 tons (10 tons with some limitations)

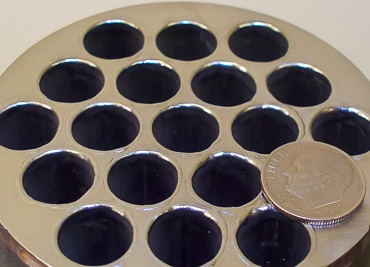

- Waterjet processing

- Precision miter cutting of tubing/structurals

- CATIA design

- In-house CWI/CWE

Equipment

- Bridge Cranes, 5-Ton (4)

- Waterjet, 2m x 4m x 280mm (80” x 155” x 11”) Cutting Envelope

- Watts W50 Weld Tester (Tensile & Bend Tests)

- Miller Dynasty 800 (1)

- Miller Dynasty 750 (1)

- Miller Dynasty 400 (1)

- Miller Dynasty 350 (1)

- Miller Dynasty 280 (1)

- Miller Syncrowave 250 (2)

- Miller MIG Welders, Various Models 300A-450A (13)

- Nelson Stud Welder, 3/8-16 (10mm) capacity

- Knee Mills (2)

- Engine Lathe, 8”

- Ironworker, 110 Ton

- Timesaver Belt Finisher, Water Cooled, 36”

- Vertical Tilt-Head Band Saw, 18”

- Horizontal Band Saw, 14”

- Vertical Band Saw 14”

- Hypertherm Powermax 65 Plasma Cutter

- Forklifts Up To 6-Ton (3)